top of page

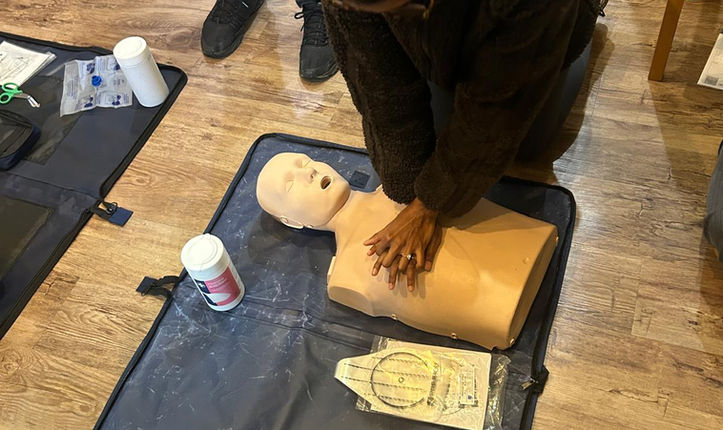

Our Basic Life Support (BLS) training for dental professionals is designed to meet the specific needs of dental teams, ensuring compliance with CQC/ HIW/ HIS and Resuscitation Council UK guidelines. Through hands-on practice and scenario-based learning, you’ll build the confidence and skills to respond to emergencies with clarity and competence.

Whether you’re a practice owner, dental nurse, hygienist, or receptionist, BLS is not just a requirement—it’s a responsibility. We make it simple, practical, and engaging.

Get in Touch to Book your BLS course

Complete the form below and we will get you booked in

Get in touch

FAQ's

BLS FAQ

bottom of page